Aluminum profiles have become an indispensable component in modern construction, engineering, and design. These adaptable extrusions provide a unique combination of lightweight, durability, and customization, making them a popular choice in a variety of sectors. In this comprehensive article, we will delve into the different types of aluminum profiles.

Understanding the Fundamentals Of Aluminum Profiles

Aluminum profiles are extruded aluminum shapes that can be tailored to meet specific design and functional requirements. These profiles are formed by driving molten aluminum through a die, resulting in their characteristic cross-sectional shape. The extrusion process allows for the creation of a vast array of profiles, from simple solid bars to complex, multi-chambered structures.

Exploring the Different Types of Aluminum Profiles

Solid Aluminum Profiles

Solid aluminum profiles are the most basic and widely used form. They come in a number of shapes, including round, square, rectangular, and more. These profiles are often utilized in structural applications, such as framing, furniture, and machinery components, where their strength and versatility are highly valued.

Extruded Aluminum Profiles

Extruded aluminum profiles are created through a process that involves forcing molten aluminum through a die to produce a specific cross-sectional shape. This technology enables the production of sophisticated and customizable profiles, making them highly adaptable in their applications. From intricate architectural designs to specialized industrial components, extruded aluminum profiles offer endless possibilities.

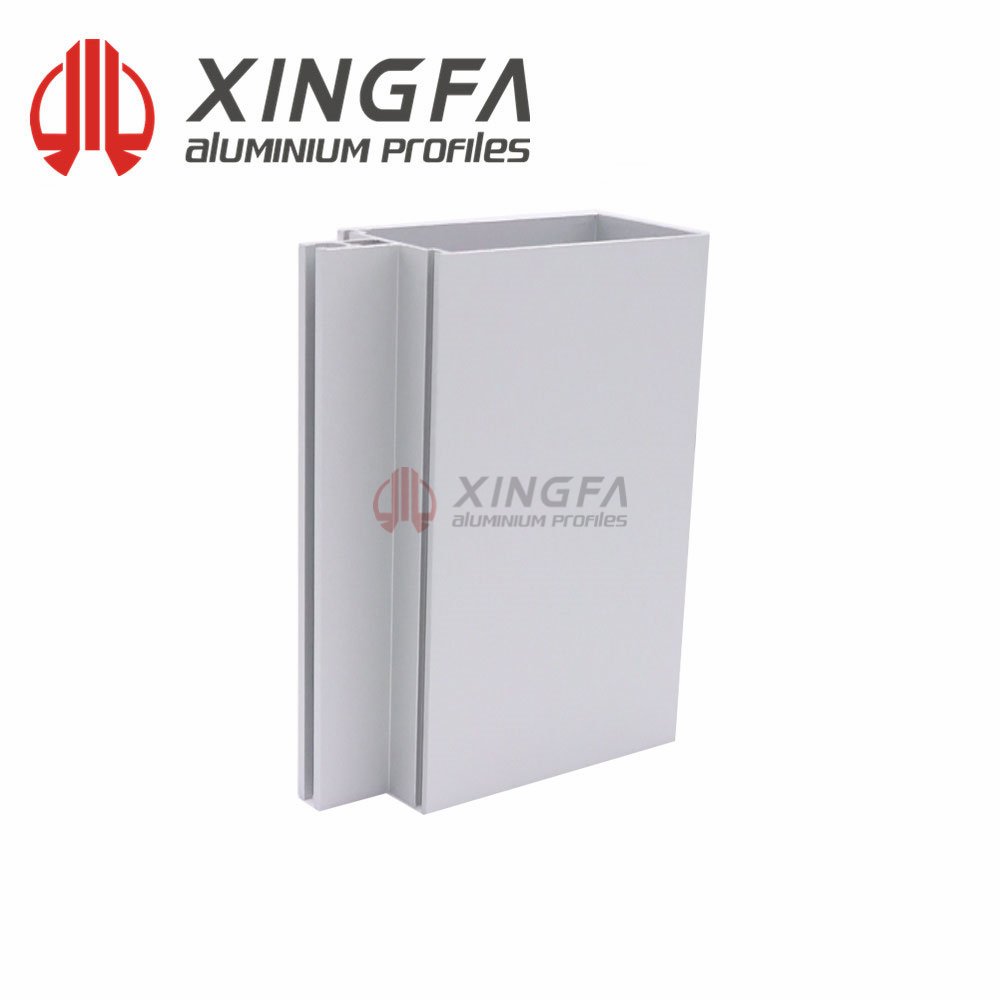

Hollow Aluminum Profiles

Hollow aluminum profiles feature an internal cavity or multiple chambers, providing a balance of strength and weight reduction. These profiles are especially useful in applications where weight is an important consideration, such as the automotive, aircraft, and transportation industries, where every ounce saved can help enhance fuel efficiency and performance.

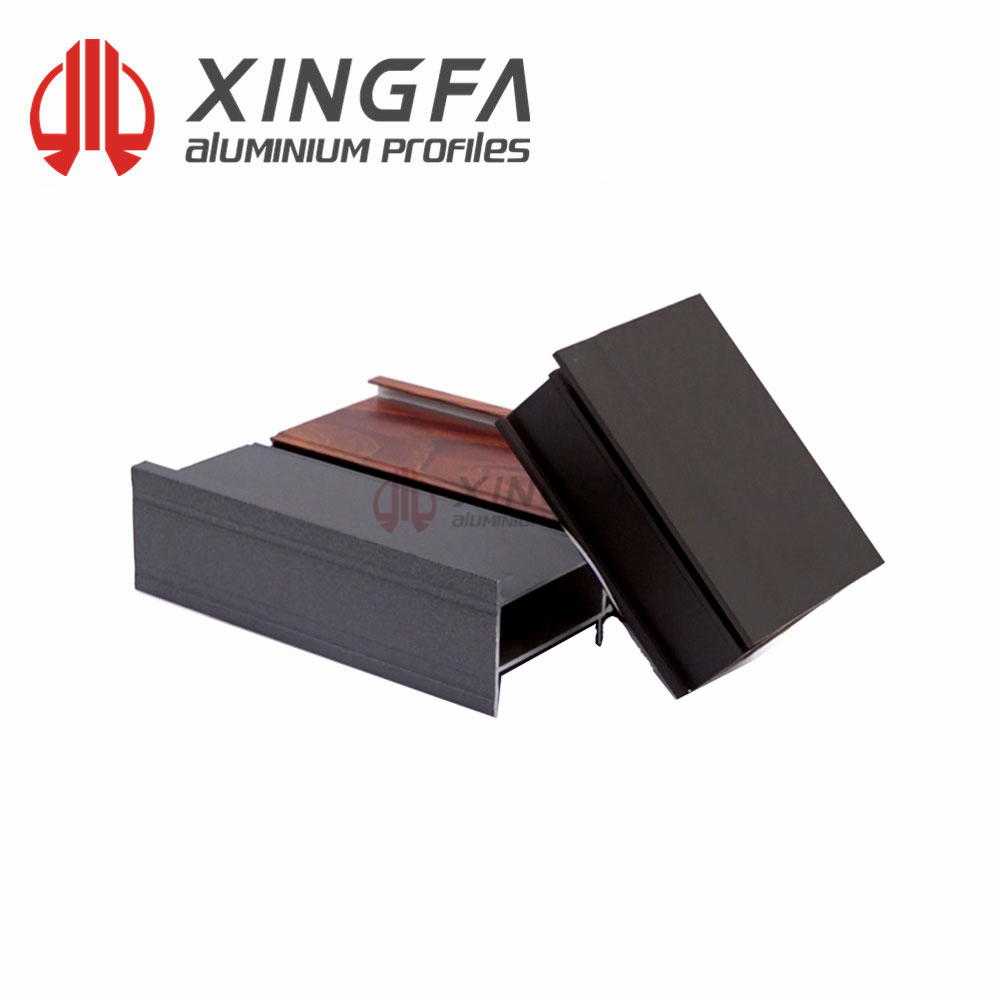

Anodized Aluminum Profiles

Anodized aluminum profiles go through an electrochemical process that improves their surface qualities, including corrosion resistance, hardness, and aesthetic appeal. This treatment creates a durable, protective oxide layer on the aluminum, making it a popular choice for applications where appearance and durability are of utmost importance, such as in the construction and design industries.

Thermal Break Aluminum Profiles

Thermal break aluminum profiles are intended to improve the thermal efficiency of a structure by minimizing heat transmission between the interior and exterior. These profiles feature a thermal barrier, typically made of a non-conductive material, that separates the inner and outer sections of the profile, minimizing energy loss and enhancing the overall thermal performance of the building or structure.

Composite Aluminum Profiles

Composite aluminum profiles combine aluminum with other materials, such as plastics or fiberglass, to create a hybrid product that offers enhanced properties. Depending on the exact composite materials employed, these profiles can provide increased strength, corrosion resistance, or thermal insulation, making them appropriate for a variety of applications ranging from construction to industrial manufacture.

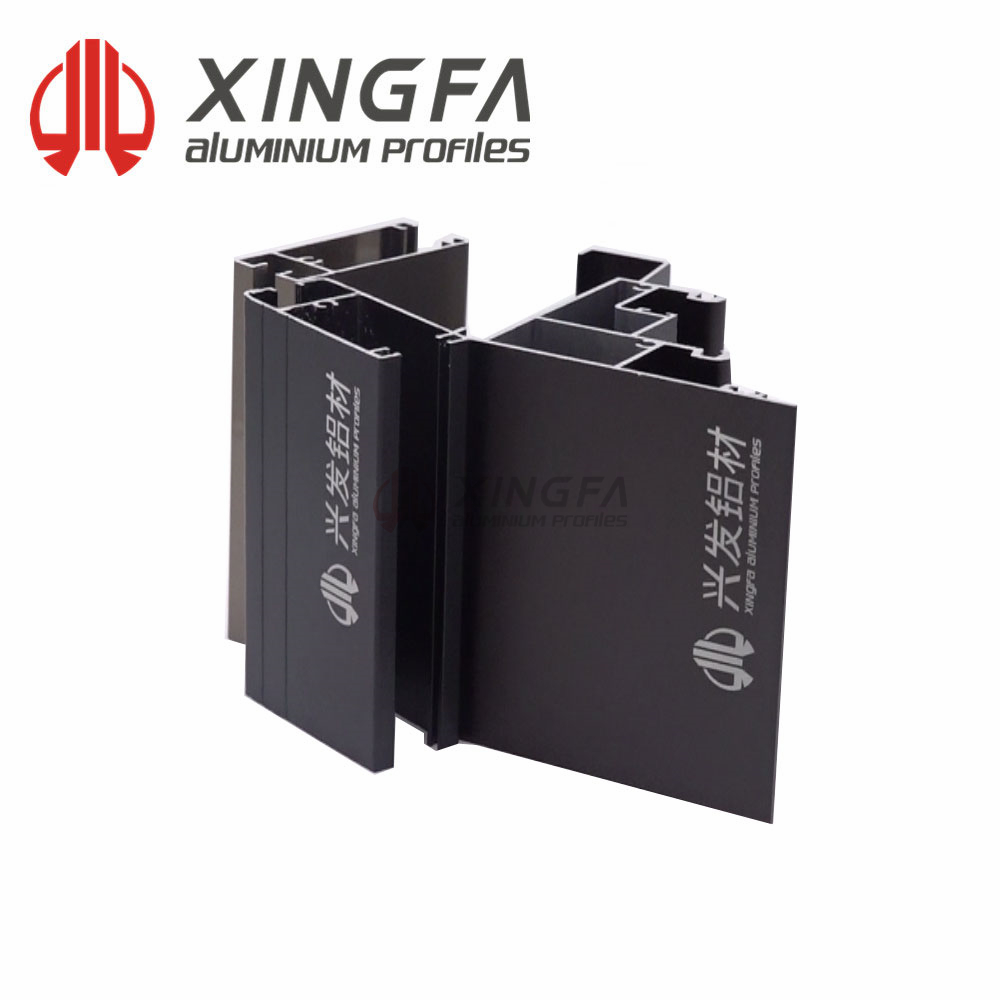

Conclusion

Aluminum profiles have become an indispensable part of modern engineering and design, offering a wide range of benefits. From the simplicity of solid profiles to the intricacy of composite and thermal break designs, the world of aluminum profiles is always evolving, offering creative solutions to fulfill the ever-changing needs of many sectors. XINGFA, as a premier aluminum profile supplier, offering a variety of aluminum profiles to suit different applications. Experience the differences in XINGFA and upgrade your business now!