In the realm of industrial materials, few possess the versatility, durability, and aesthetic appeal of aluminum. Among its many forms, anodized aluminum extrusion is a prime example of technological innovation and practical utility. In this comprehensive guide, we delve into the intricacies of anodized aluminum extrusion.

What Is Anodized Aluminum?

Anodized aluminum refers to the process of creating a layer of oxide on the surface of aluminum through electrolytic passivation. This procedure improves the metal’s corrosion, wear, and aesthetic properties. Anodized aluminum extrusion involves the shaping of aluminum profiles through the extrusion process, followed by anodizing to achieve the desired properties.

Composition and Manufacturing Process

Composition of Anodized Aluminum

Anodized aluminum extrusion normally begins with high-quality aluminum alloys selected for their unique mechanical qualities and surface finish requirements. These alloys often include elements such as silicon, magnesium, and manganese, which contribute to the material’s strength and formability.

Manufacturing Process

The manufacturing process of anodized aluminum extrusion involves several key steps:

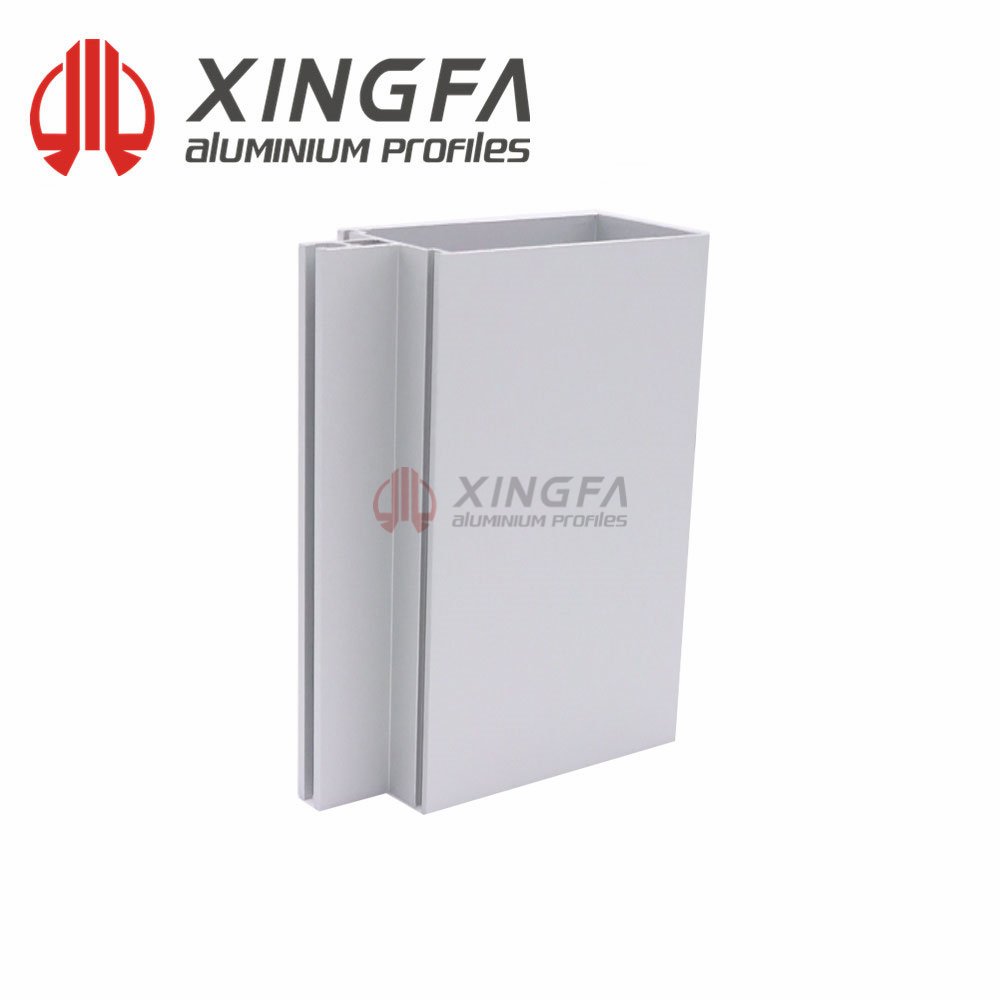

Extrusion: The process begins with the heating of aluminum billets to a temperature where they become malleable. These billets are then forced through a die to create the desired shape, forming aluminum profiles of various cross-sectional geometries.

Anodizing: After extrusion, the aluminum profiles undergo anodizing. This electrochemical process involves immersing the profiles in an electrolytic solution and applying a direct current. This causes an oxide layer to form on the surface of the aluminum, resulting in improved corrosion resistance and durability.

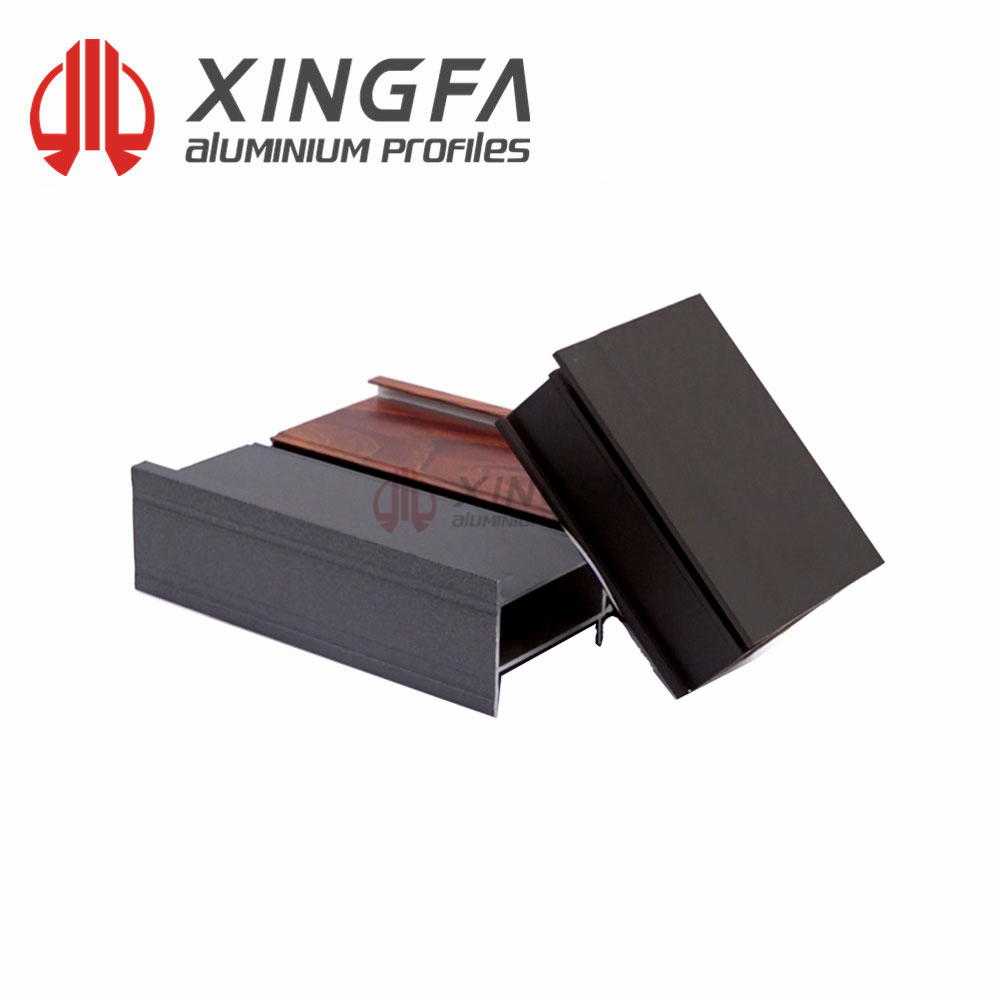

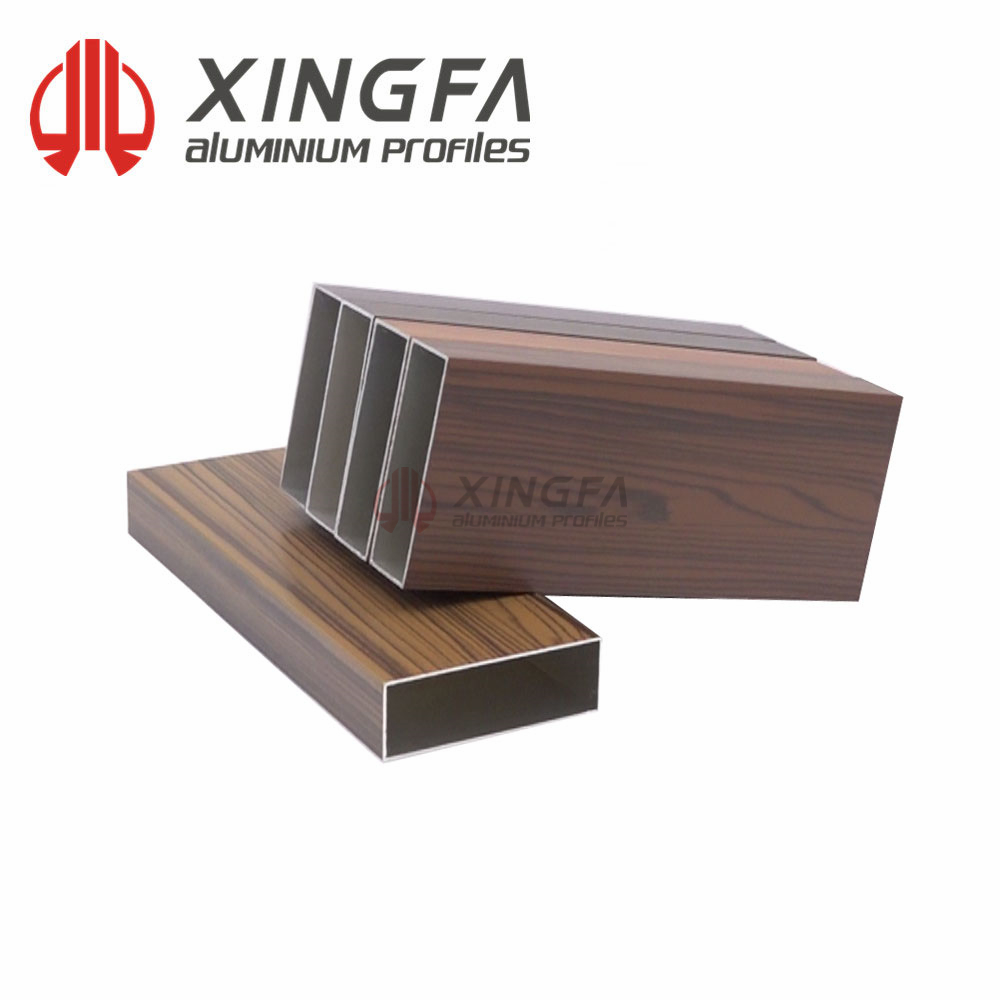

Coloring (Optional): In some cases, an additional step involves coloring the anodized aluminum profiles. This can be achieved through the use of organic dyes or metallic salts, offering a wide range of color options to suit different aesthetic preferences.

Applications of Anodized Aluminum Extrusion

Anodized aluminum extrusion finds widespread applications across various industries due to its unique combination of properties. Some common applications include:

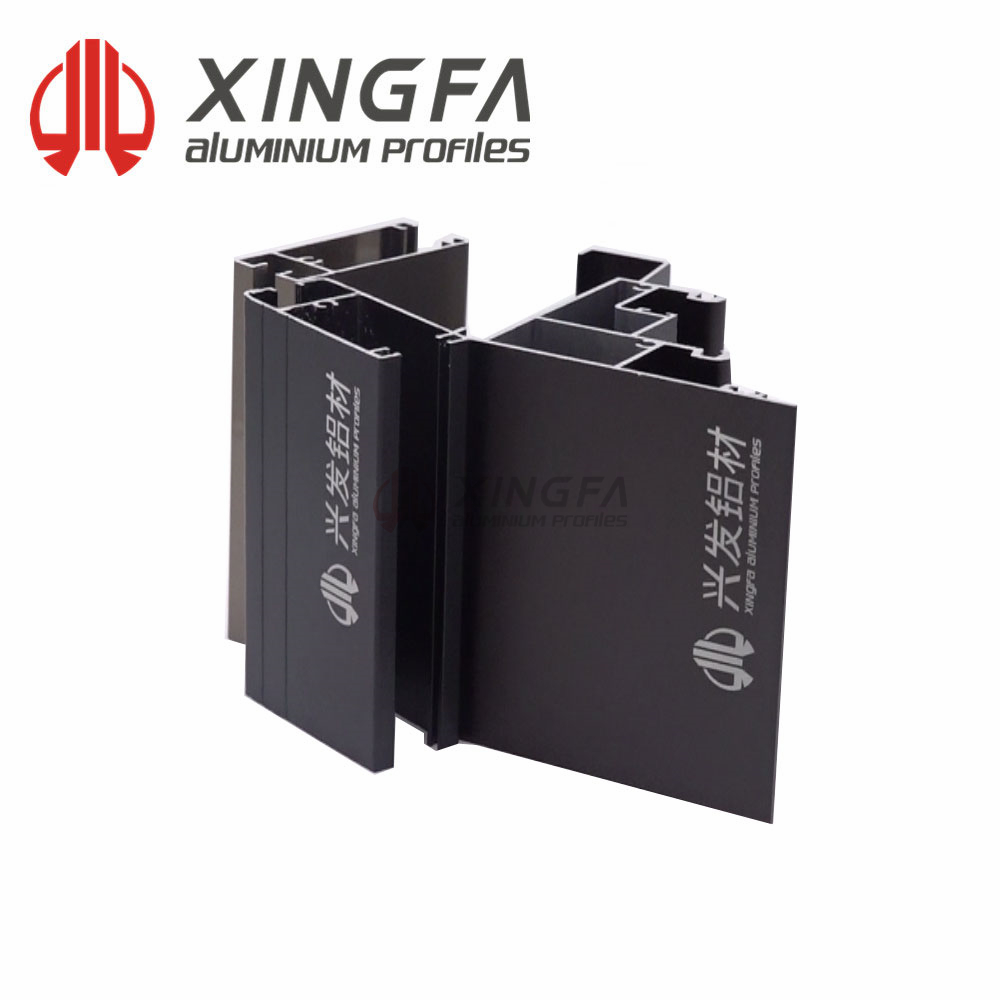

Architectural: Anodized aluminum extrusion is widely utilized in architectural applications such as window frames, curtain walls, doors, and railings because of its corrosion resistance and ability to handle extreme environmental conditions.

Custom Aluminum Extrusion Profiles

Automotive: In the automotive industry, anodized aluminum extrusion is utilized for components like trim, body panels, and structural parts, where lightweight, corrosion-resistant materials are essential for performance and longevity.

Electronics: Anodized aluminum extrusion is used in electronic enclosures, heatsinks, and chassis because of its high thermal conductivity, electrical insulation, and durability.

Consumer Goods: From furniture and lighting fixtures to sporting equipment and appliances, anodized aluminum extrusion is favored for its aesthetic appeal, durability, and versatility in manufacturing.

Benefits of Anodized Aluminum Extrusion

The popularity of anodized aluminum extrusion stems from a myriad of benefits it offers, including:

Enhanced Durability: The anodizing process forms a protective oxide layer on the surface of the aluminum, greatly enhancing its resistance to corrosion, scratches, and wear.

Improved Aesthetics: Anodized aluminum extrusion is available in a number of colors and finishes, allowing for customization to fit individual design needs and aesthetic preferences.

Lightweight: Aluminum is inherently lightweight, making anodized aluminum extrusion an ideal choice for applications where weight savings are crucial, such as in the aerospace and automotive industries.

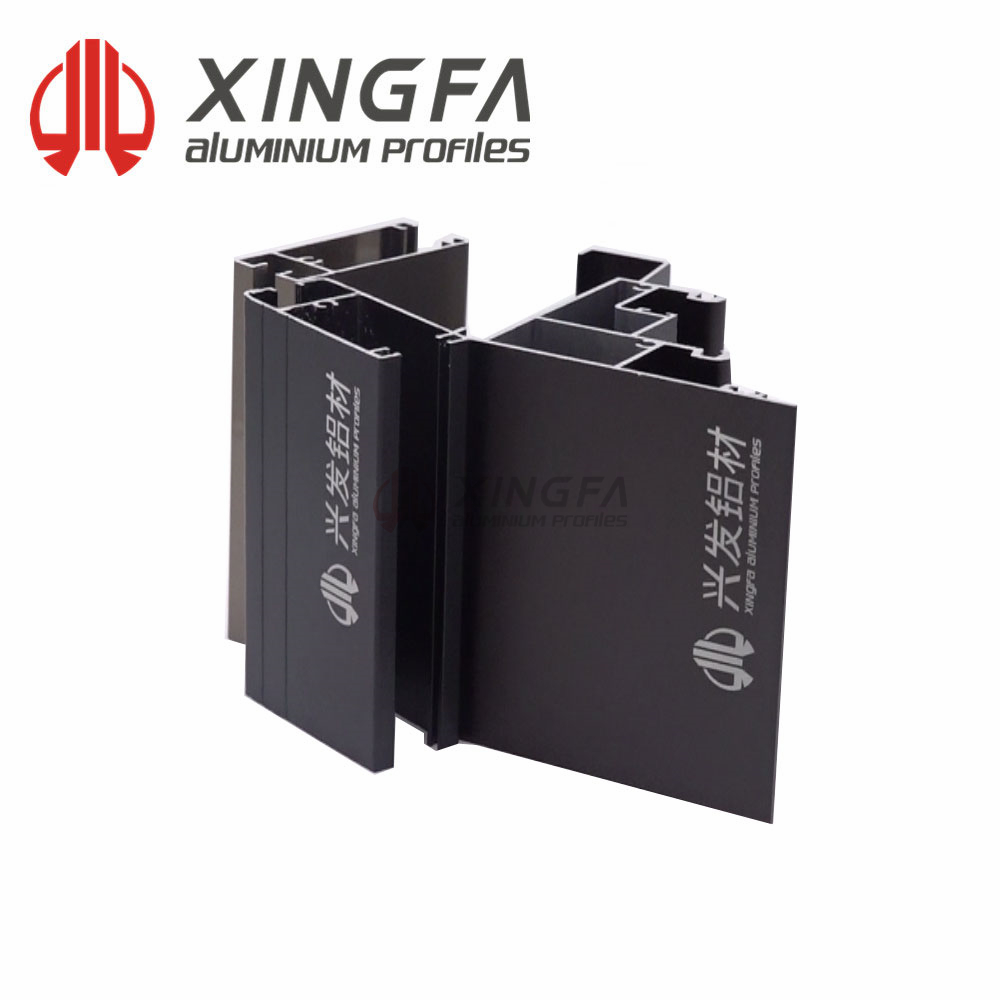

Aluminium Profiles Manufacturer

Environmental Sustainability: Aluminum is largely recyclable, and the anodizing process improves its sustainability by extending its life and decreasing maintenance requirements.

Thermal Conductivity: Anodized aluminum extrusion exhibits excellent thermal conductivity, making it suitable for applications where heat dissipation is essential, such as in electronic enclosures and heatsinks.

Conclusion

Anodized aluminum extrusion represents a pinnacle of modern engineering, combining the inherent properties of aluminum with the benefits ideal for a wide range of applications. If you are looking for high-quality anodized aluminum extrusions, XINGFA is ideal for you. Please feel free to contact us at alusupplier@xingfa.com for further information about our top-quality anodized aluminum extrusion processing!