Aluminum profiles are essential components in various industries, ranging from construction and architecture to automotive and aerospace. These adaptable materials are durable and lightweight and provide design versatility. However, with so many alternatives, choosing the proper aluminum profiles for your project can be a difficult challenge. This guide aims to simplify the selection process and help you make informed decisions based on your specific requirements.

Understand Your Project Requirements

Understanding your project requirements is the cornerstone of selecting the right aluminum profiles. This step involves thorough analysis and consideration of various factors that will influence your choice. For instance, if you’re designing a structure that will bear heavy loads, such as a machinery frame or a structural framework, you’ll need profiles with high load-bearing capacity and structural integrity. On the other hand, if your project incorporates architectural aspects where aesthetics are important, you may prefer profiles with sleek designs and appealing finishes. By explicitly outlining your project requirements, you may reduce your selections and focus on profiles that best meet your objectives.

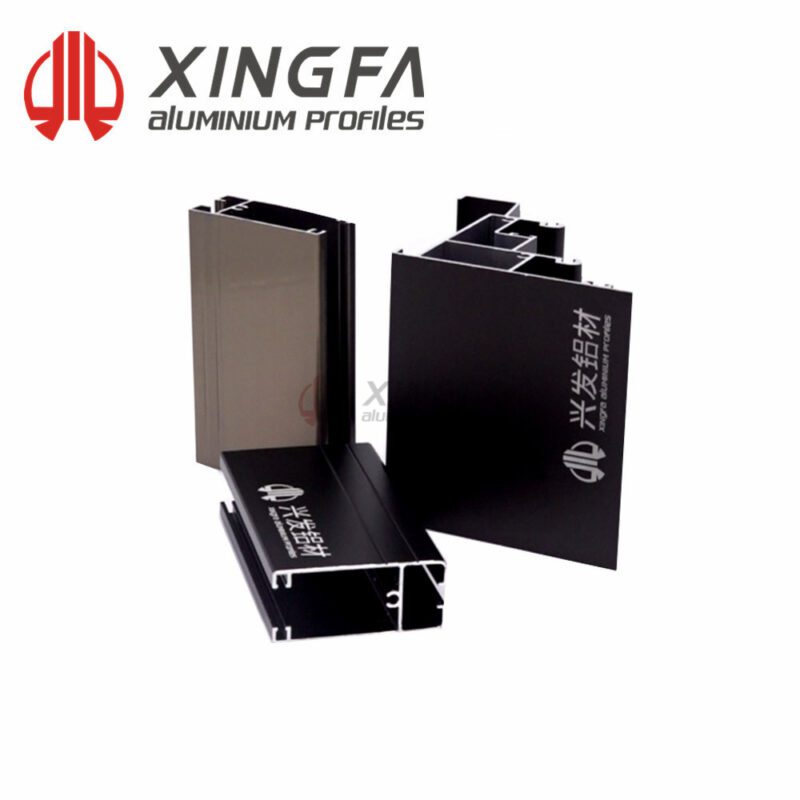

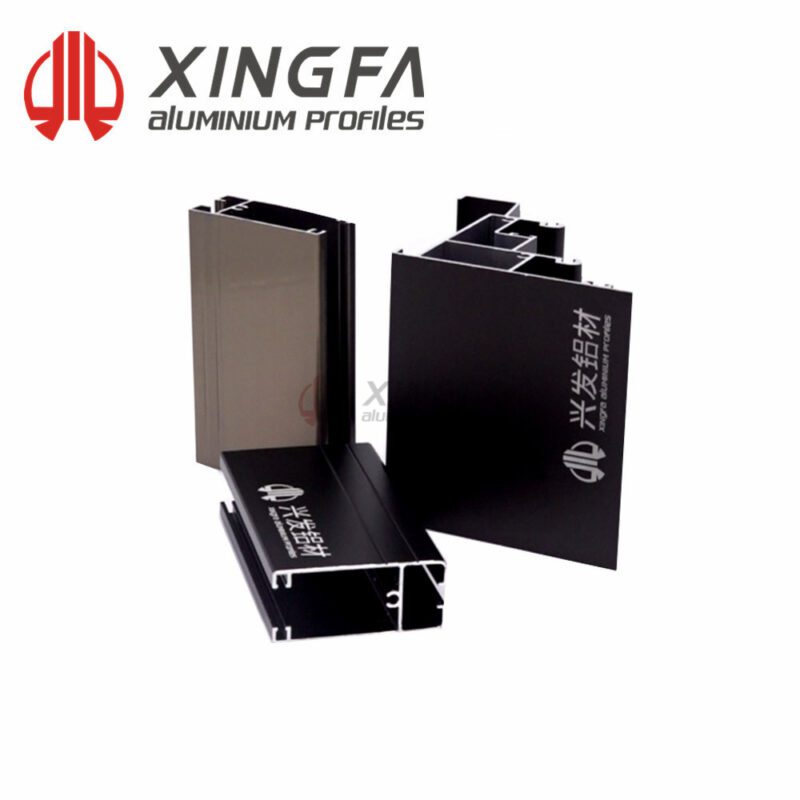

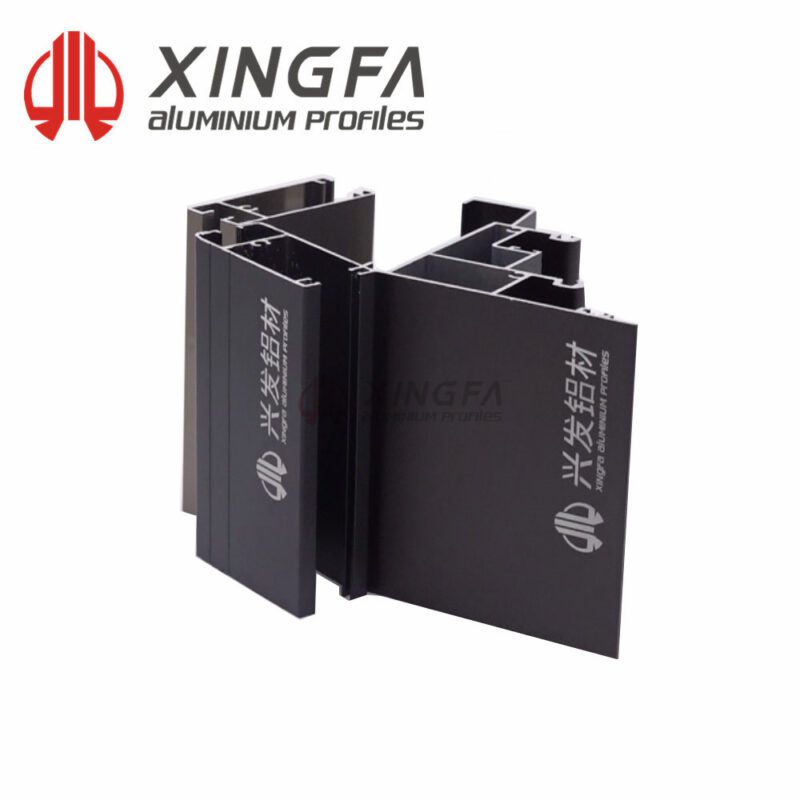

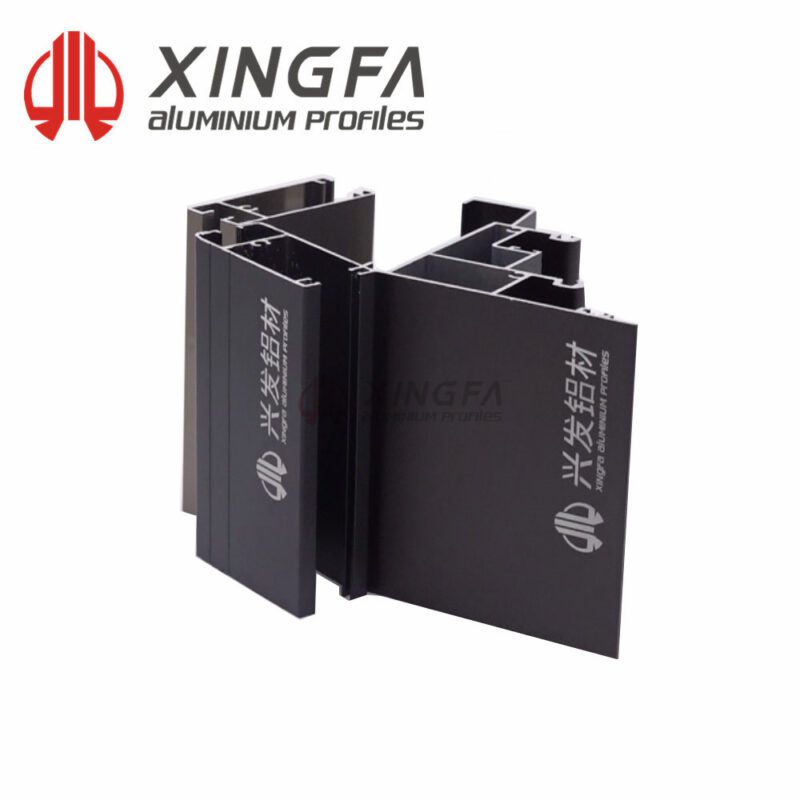

Aluminium Profile Manufacturer

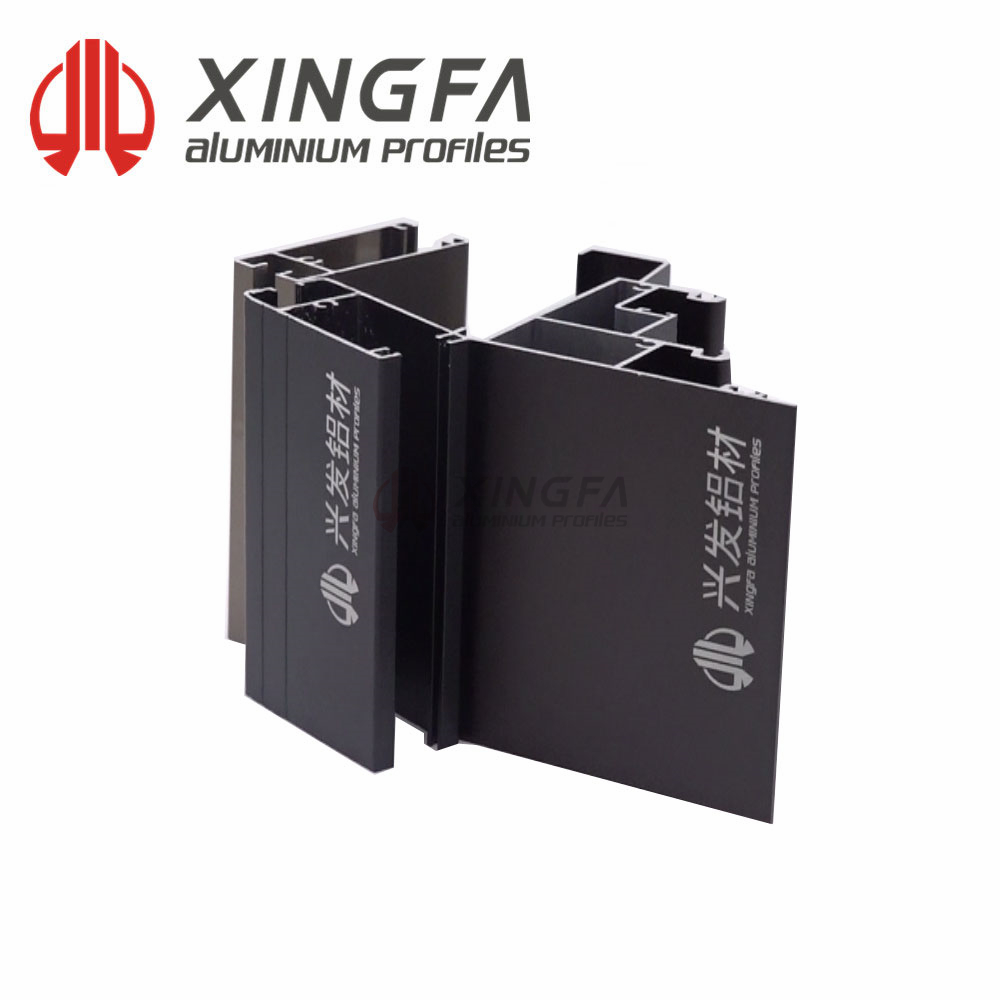

Identify Profile Types

Aluminum profiles come in a wide range of shapes and configurations, each offering distinct advantages for different applications. Understanding the characteristics of each profile type is essential for choosing the right one for your project. T-slot profiles, for example, have slots along the length of them, making it simple to attach accessories and components with bolts and fasteners. These profiles are extremely adaptable and are widely utilized in applications such as machine guarding, workstations, and automated systems. Conversely, angle profiles are L-shaped and provide structural support and stability, making them suitable for constructing frames, racks, and shelving systems. You can ensure optimal performance and functionality by identifying the most suitable profile type for your specific application.

Evaluate Material Specifications

Aluminum profiles are available in various alloys, each with its own set of mechanical properties and performance characteristics. The most often used alloys for extruded aluminum profiles are 6061 and 6063, which provide a good combination of strength, machinability, and corrosion resistance. However, other alloys may be better suited for specific applications. For instance, 7000-series alloys offer higher strength but may be more challenging to extrude and machine. By examining material criteria such as alloy composition, mechanical qualities, and surface finish compatibility, you can find the best material for your project.

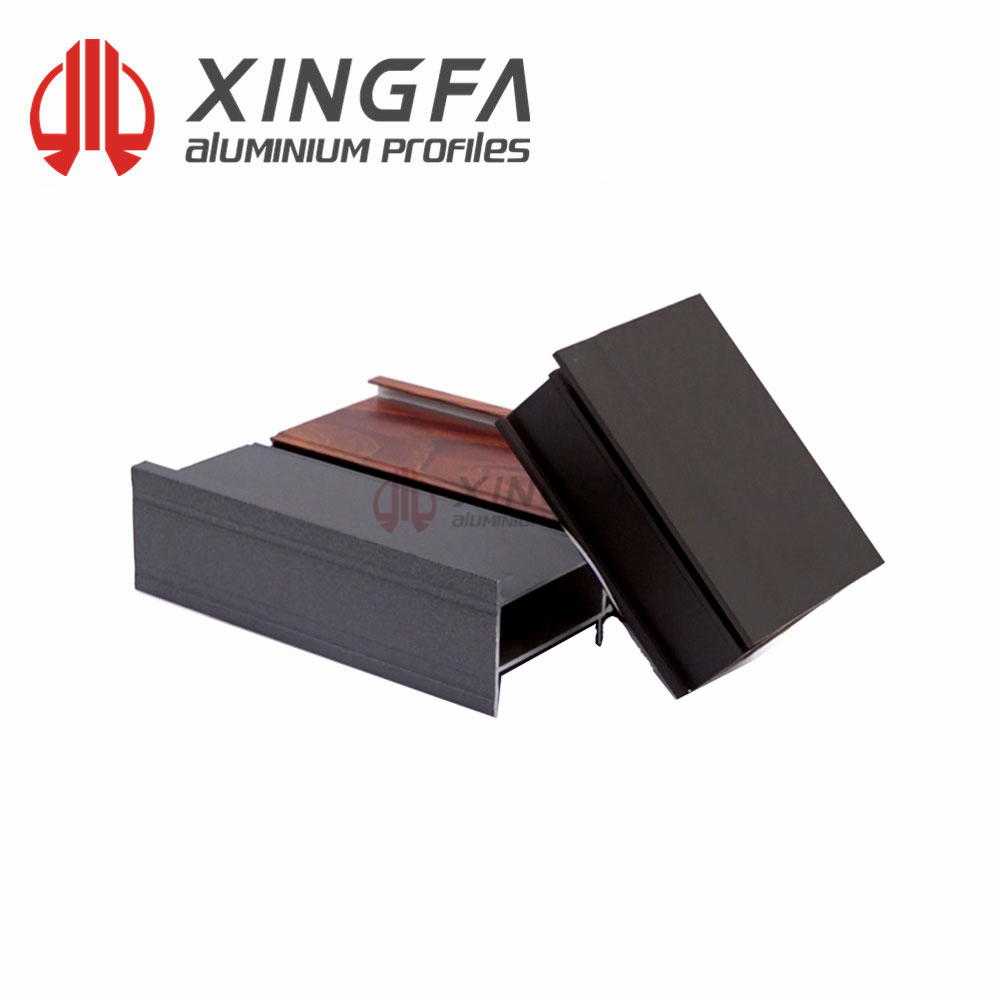

Consider Surface Finish

The surface finish on aluminum profiles not only improves their appearance but also protects them from corrosion, wear, and environmental harm. Anodizing is a common surface treatment method that creates a durable oxide layer on the aluminum surface, enhancing its corrosion resistance and providing a range of color options. Powder coating is another popular finish that offers excellent durability and a wide variety of colors and textures. Additionally, polishing can be used to achieve a smooth, reflective surface finish, ideal for decorative or high-end applications. You can select the best surface finish for your aluminum profiles based on the intended aesthetic appeal, durability, and performance requirements.

Evaluate Manufacturing Capabilities

When selecting aluminum profiles, it’s essential to consider the manufacturing capabilities of your supplier. The extrusion process plays a crucial role in determining the dimensional accuracy, surface finish quality, and mechanical properties of the profiles. Choose a reliable manufacturer with cutting-edge extrusion equipment, competent engineers, and rigorous quality control procedures. Additionally, consider whether the manufacturer offers secondary operations such as cutting, machining, and assembly services to meet your project’s specific requirements. You can ensure that your aluminum profiles are of consistent quality and delivered on time by partnering with a dependable provider with extensive manufacturing capabilities.

Assess Cost and Budget

Cost considerations are an integral part of the decision-making process when choosing aluminum profiles for your project. While it’s essential to prioritize quality and performance, you must also manage costs effectively to stay within budget constraints. Compare prices from multiple suppliers and consider factors such as material quality, surface finish, lead times, and additional services offered. Look for vendors who provide affordable pricing without compromising quality or service. Consider the long-term financial implications of using high-quality profiles that require little maintenance and provide higher durability. By carefully evaluating costs and budgeting accordingly, you can maximize the value of your investment in aluminum profiles.

Conclusion

By following these steps and conducting thorough research, you can select aluminum profiles that meet your needs and deliver exceptional results. If you are looking for a trusted aluminum profile supplier, XINGFA is ideal for you. We offer a wide range of aluminum profiles to meet different applications. Come and get more details from our site now!